Combustion in SI Engine

The combustion process

is defined as a rapid chemical reaction between the H2 and C with

oxygen in the air and liberates energy in the form of heat. It is not the

purpose of this article to study the combustion of fuel in details as it is

very complicated phenomenon. The purpose of this article is just to introduce

the combustion in SI engines and effects of different parameters on the

combustion and ultimately the effects on engine performance.

It is absolutely

essential to burn the fuel supplied completely for the economical working of

the engine and also for the safety of the engine and environment. Therefore,

the mixture supplied to the engine should possess A:F ratio otherwise,

combustion cannot be initiated or if initiated it cannot be sustained. In

addition to this, there must be some means to initiate the combustion and the

generated flame should be able to propagate through the mixture and burn the

mixture completely.

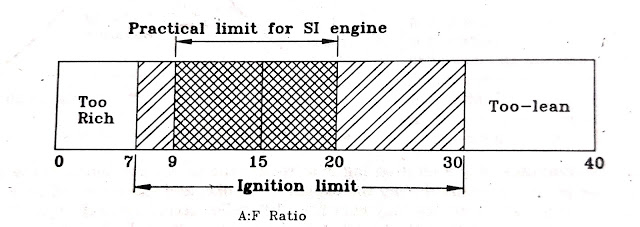

It is known fact that

the fuel vary with A:F ratio cannot be burned. There is a ignition limit

for any fuel to start the combustion and sustain it till the complete fuel

burns by the flame generated with spark plug. In addition to this, the

temperature of the mixture to initiate the ignition is equally important. It is

also known that the flame will propagate if the temperature of the burnt gases

exceeds 1500 K for SI engine fuels. The ignition limits of hydrocarbon fuel

when temperature of mixture reaches to 1500 K are shown in the figure given

below:

The upper and lower

limit of A:F ratio for ignition depends upon the temperature of a particular

fuel. The limit becomes wider at higher temperatures because of higher reaction

rate and higher thermal diffusivity coefficients of the mixture. Therefore, it

is very essential to see that the A:F ratio of the mixture supplied to the

engine should lie in the practical limit as shown in the figure.

Stages of Combustion in

SI Engines:

It is assumed that the

heat is added instantaneously of constant volume in the ideal air-cycle of SI

engine. To achieve this, the burning of the fuel in the SI engine should be

instantaneous. In actual engines, combustion occurs over a finite period of time

as the flame starting around the spark plug has to propagate through the entire

mixture of the air and fuel.

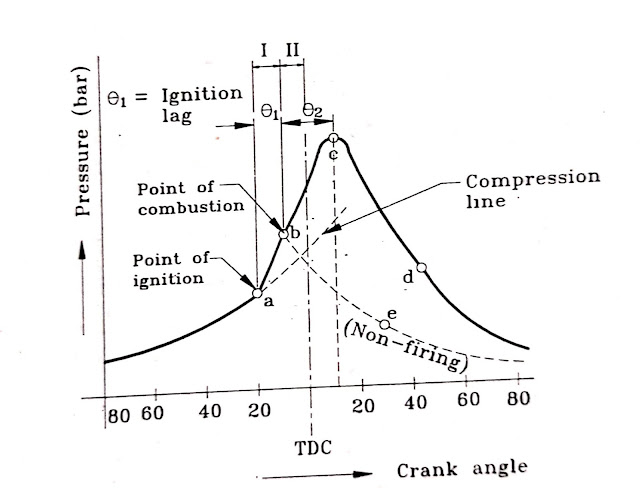

The pressure variation

in the SI engine combustion chamber during the crank rotation is shown in the

figure given below. This is really an unfolded p-v diagram.

The ignition is timed

to take place at the point ‘a’ but the burning commences only at the point ‘b’.

The time interval between these two points is known as “Ignition lag”.

The major disadvantage of the ignition lag is that it reduces the power

developed. If the ignition lag is too long, the peak pressure occurs during the

expansion stroke, and therefore full advantage of expansion is not achieved.

All consideration should be taken into account in the design of the combustion

chamber and selecting the fuel used to reduce the ignition lag.

The theoretical diagram

of combustion is shown in the figure:

But actual process

differs from theoretical as instant combustion is not possible as shown by bc.

The combustion to start takes small time after giving the spark as the

surrounding mixture is to be heated up to ignition temperature and then formed

nucleus of flame starts propagating through the surrounding mixture.

The pressure variation

in the engine with respect to the crank angle is shown in the figure. There are

mainly three stages of combustion in SI engines as shown in the figure.

1.

First Phase:

This

phase is considered between the point of ignition and point of combustion. As

shown in figure, ignition is timed at the point ‘a’ and combustion starts at

the point ‘b’. The period of ignition lag is very small and lies between

0.00015 to 0.002 seconds. An ignition lag of 0.002 sec corresponds to 350 crank

rotation when the engine is running at 3000 RPM and crank angle required (which

is also known as angle of advance) increases with an increase in engine speed.

2.

Second Phase:

Once

the flame formed at the point ‘b’, it should be self-sustained and must to able

to propagate through the mixture. This is possible when the rate of heat

generation by burning the surrounding mixture of the flame nucleus must be

higher than the heat lost by the flame to the surrounding. As the difference

between heat generation and heat lost is higher, the rate of flame propagation

is higher and complete combustion will occur earliest possible this is most

desirable requirements of combustion in SI engines. The propagation of flame

also depends upon the flame temperature as well as temperature and density of

the surrounding mixture as its propagation is directly proportional to these

factors. Weak spark and low compression ratio (as density of mixture is less)

gives low propagation of the flame.

After

the point ‘b’, the flame propagation is abnormally low at the beginning as heat

loss is more than the heat generated. Therefore, the pressure rise is also slow

as mass of mixture burned is small. Therefore, it is necessary to provide angle

of advance 30 to 350 if the peak pressure is to be attained 5 to 100

after TDC.

After

the point ‘c’, the pressure starts falling due to the fall in the rate of heat

release when the flame reaches the wall in the last part of combustion and

cannot compensate for its fall due to gas expansion, and heat transfer to the

walls.

The

time required for the flame to travel 95% of the chamber length with respect to

speed of the engine is shown in the figure below:

It

is obvious, the crank angle required for 95% travel increases with increasing

RPM (the time available is decreased), therefore, if the combustion is to be

completed at point ‘c’, the angle of advance must be increased with increasing

RPM. The flame speed increases with increasing RPM because of increase in

turbulence of the mixture.

The

time required for the crank to rotate through an angle Ѳ2 is known

as combustion period during which the propagation of the flame takes place.

The

stage I and II are not entirely distinct. The starting point of stage II is

measurable as rise in pressure can be seen on p- Ѳ diagram. This is the point

where the line of combustion departs from the line of compression.

3.

Third Phase:

Although

the point ‘c’ represents the end of flame travel, it does not assure the

complete combustion of fuel. In this case, the combustion still continues after

attaining the peak pressure also and this combustion is known as After

Burning. This is continued throughout the expansion stroke. This

generally happens when the rich mixture is supplied to the engine.